MASKING, PACKING, & RACK DESIGN

At Giering Metal Finishing, we provide expert masking, packaging, and rack design solutions to ensure your parts are precisely finished and securely delivered.

Masking & Packaging in North America

Connecticut's Masking Specialists

Masking is essential when specific areas of a part must remain free of coatings. Our engineers specialize in designing custom masking solutions that ensure precise, consistent lines of demarcation. This eliminates unnecessary rework and reduces costs while maintaining the highest quality standards. Whether your project requires intricate masking for complex components or high-volume jobs with labor-intensive masking requirements, we have the expertise to meet your needs.

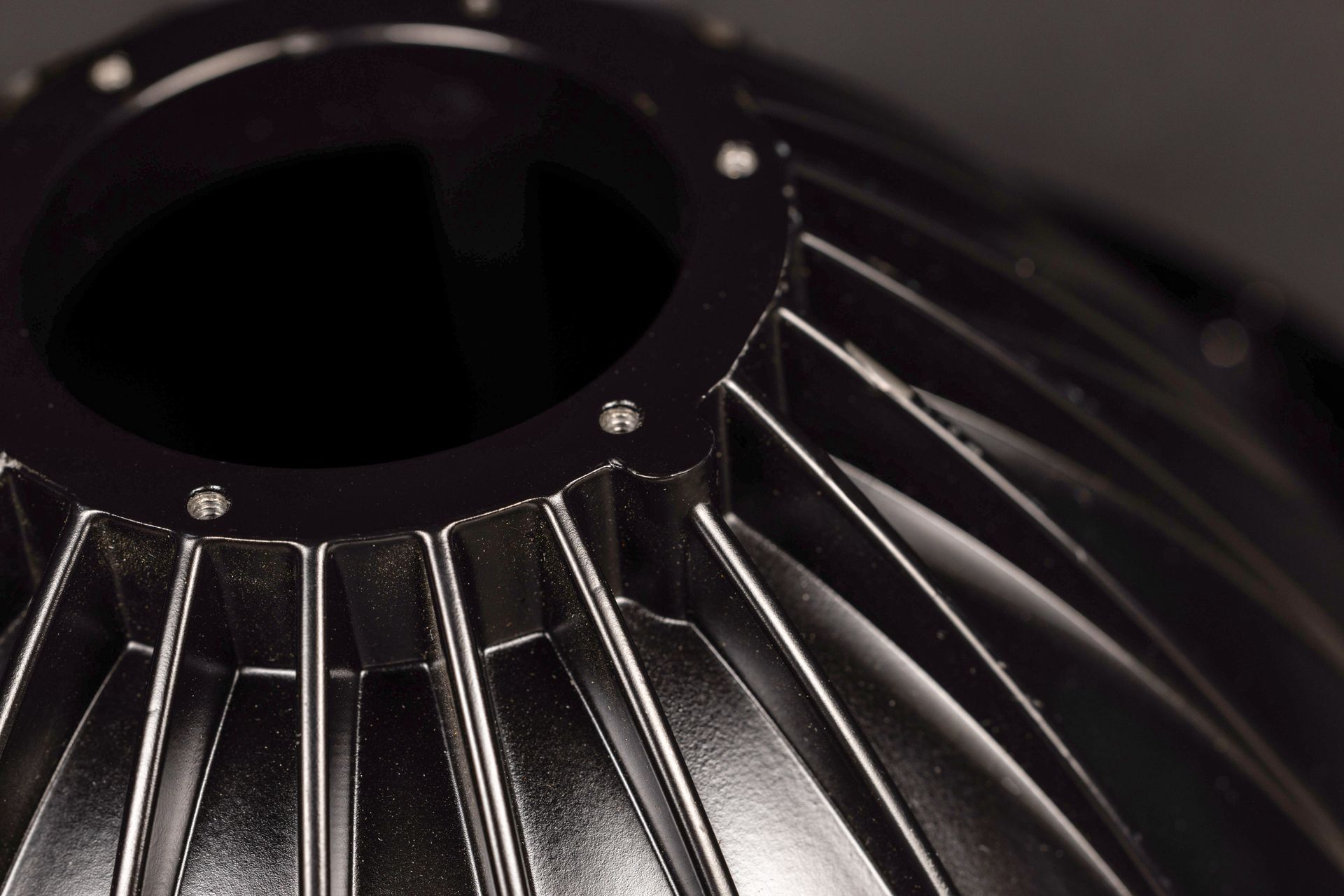

Custom Rack Design

Rack design is a critical aspect of achieving high-quality coating results. At Giering Metal Finishing, we excel in engineering custom racks and fixtures to accommodate challenging parts, including those with strict rack mark limitations or difficult geometries. Our custom racks:

Substrates We Work With

As the final step in the finishing process, packaging is key to protecting your parts during transportation and storage. Giering Metal Finishing offers a wide variety of packaging options, including:

Partner With Us for High Level Metal Finishing

At Giering Metal Finishing, our masking, packaging, and rack design services are engineered to ensure precision, efficiency, and cost savings. From custom masking and innovative rack designs to tailored packaging solutions, we deliver high-quality results that protect your parts and streamline your production process.

Let’s get started—call us at (203) 248-5583 or contact us today.

RELATED SERVICES

Quality & CONSISTENCY

Unmatched Quality, Proven Standards

At Giering Metal Finishing, quality is the cornerstone of everything we do. Utilizing advanced tools and rigorous quality control processes, we ensure each finish meets the highest standards for durability, consistency, and performance. From precise film thickness measurements to meticulous inspections, our team works diligently to adhere to your exact specifications.

Whether it's achieving flawless finishes, color matching, or delivering unmatched corrosion protection, our commitment to excellence ensures consistent results across every batch.

See our Specifications page for a list of the Military, Automotive & OEM powder coating specifications that we process.

industries

Common Uses for Masking, Packing, & Rack Design

Masking is critical for industries like aerospace and automotive, ensuring precise coating on parts with strict tolerances. Custom rack design supports efficient processing in sectors like defense and medical, handling complex or high-volume parts. Packaging protects finished components for industries like electronics and industrial equipment, ensuring safe transport and storage.

Frequently asked questions

Why is masking important in the coating process?

Masking ensures that specific areas of a part remain uncoated, providing precision and protecting functional surfaces. This is especially important in industries like aerospace, automotive, and medical where accuracy is critical.

What is the role of custom rack design?

Custom racks securely hold parts during coating and curing, ensuring uniform application and minimizing defects. They are particularly valuable for handling complex geometries or high-volume production runs in industries like defense and manufacturing.

Can you handle high-volume or specialized jobs?

Yes, we specialize in designing efficient masking and rack systems for high-volume jobs, reducing labor costs and increasing production rates. Our packaging solutions can also be scaled to fit any volume, ensuring secure delivery of all parts.

WHY CHOOSE US

Choosing Giering Metal Finishing means partnering with a team committed to precision, quality, and reliability. With decades of expertise, cutting-edge technology, and trusted relationships with fellow finishers, we deliver tailored solutions and reliable recommendations beyond our specialty.

70 Years of Experience

Decades of proven expertise in solving complex challenges.

Comprehensive Capabilities

We offer a full range of finishing services under one roof.

Customized Solutions

Every project is tailored to meet specific industry and requirements.

Exceptional Support

Our team works closely with you, providing transparency.

Need it fast?

Expedited Services Tailored to Your Deadlines

At Giering Metal Finishing, we understand that sometimes strict deadlines call for urgent solutions. Our expedited services ensure your order is prioritized and completed faster than standard lead times, helping you stay on track without compromising quality.