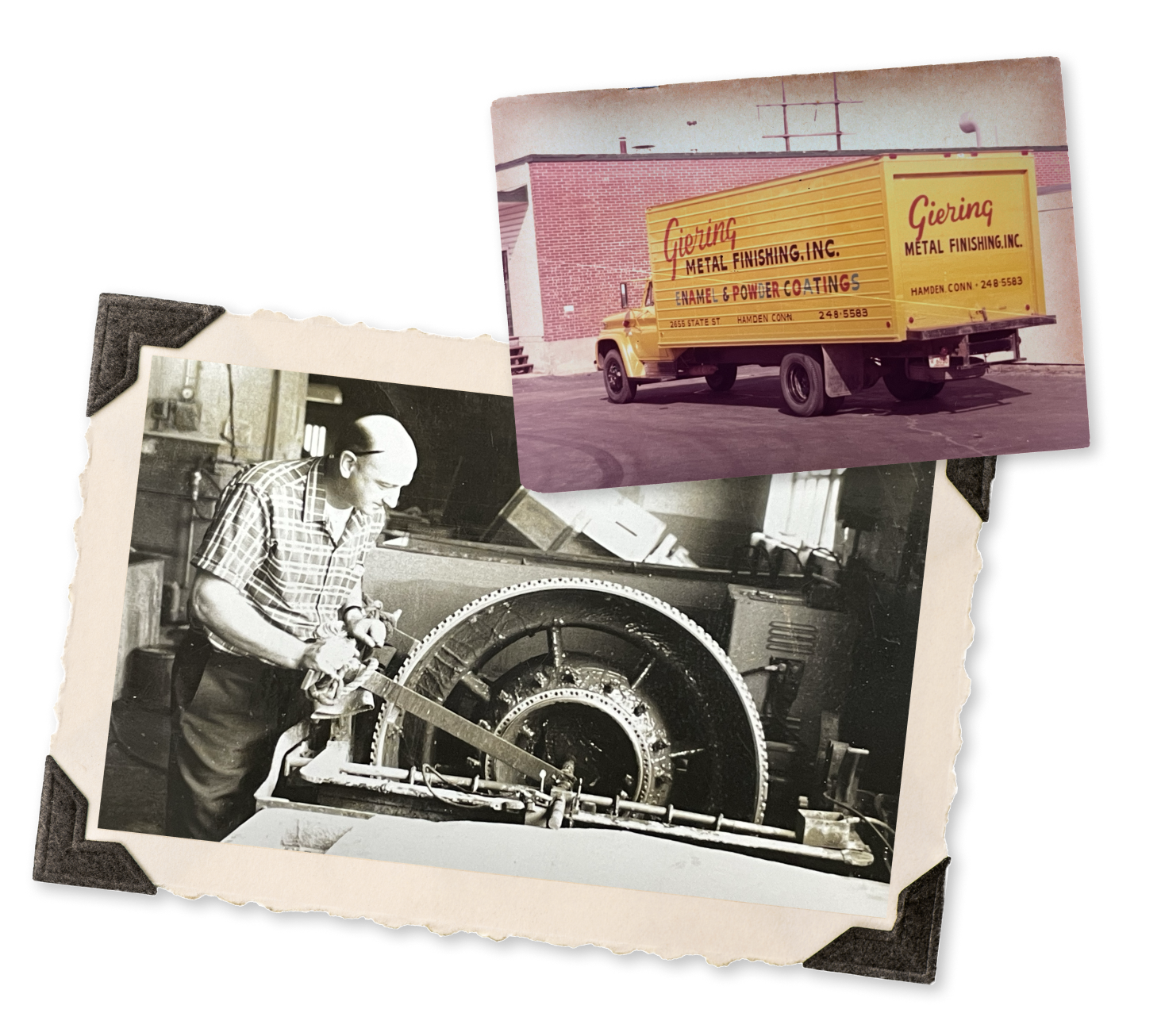

METAL FINISHING

AT ITS BEST SINCE 1954

Providing Metal Finishing Services for Over 70 Years - ISO Certified & ITAR Registered

about us

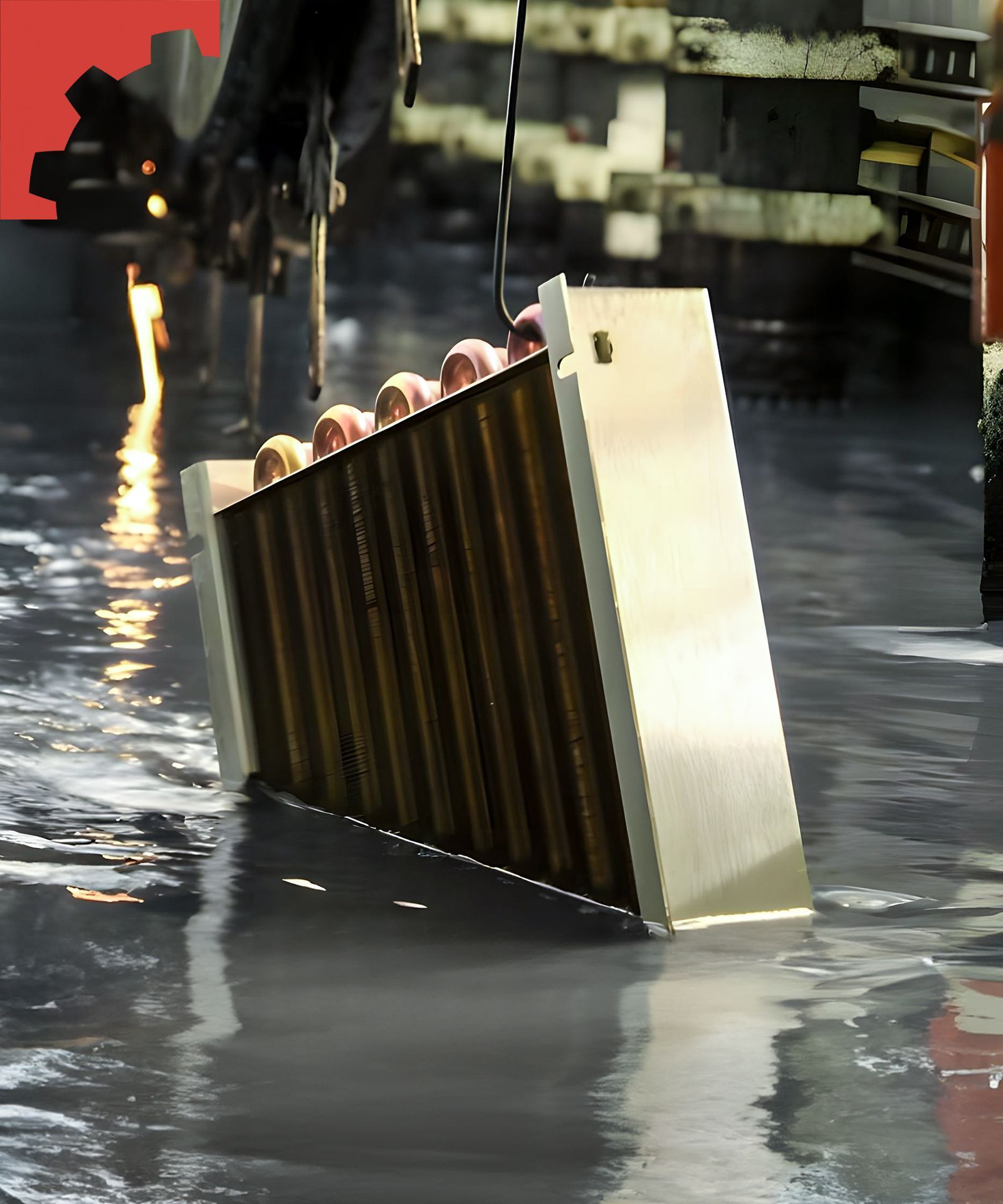

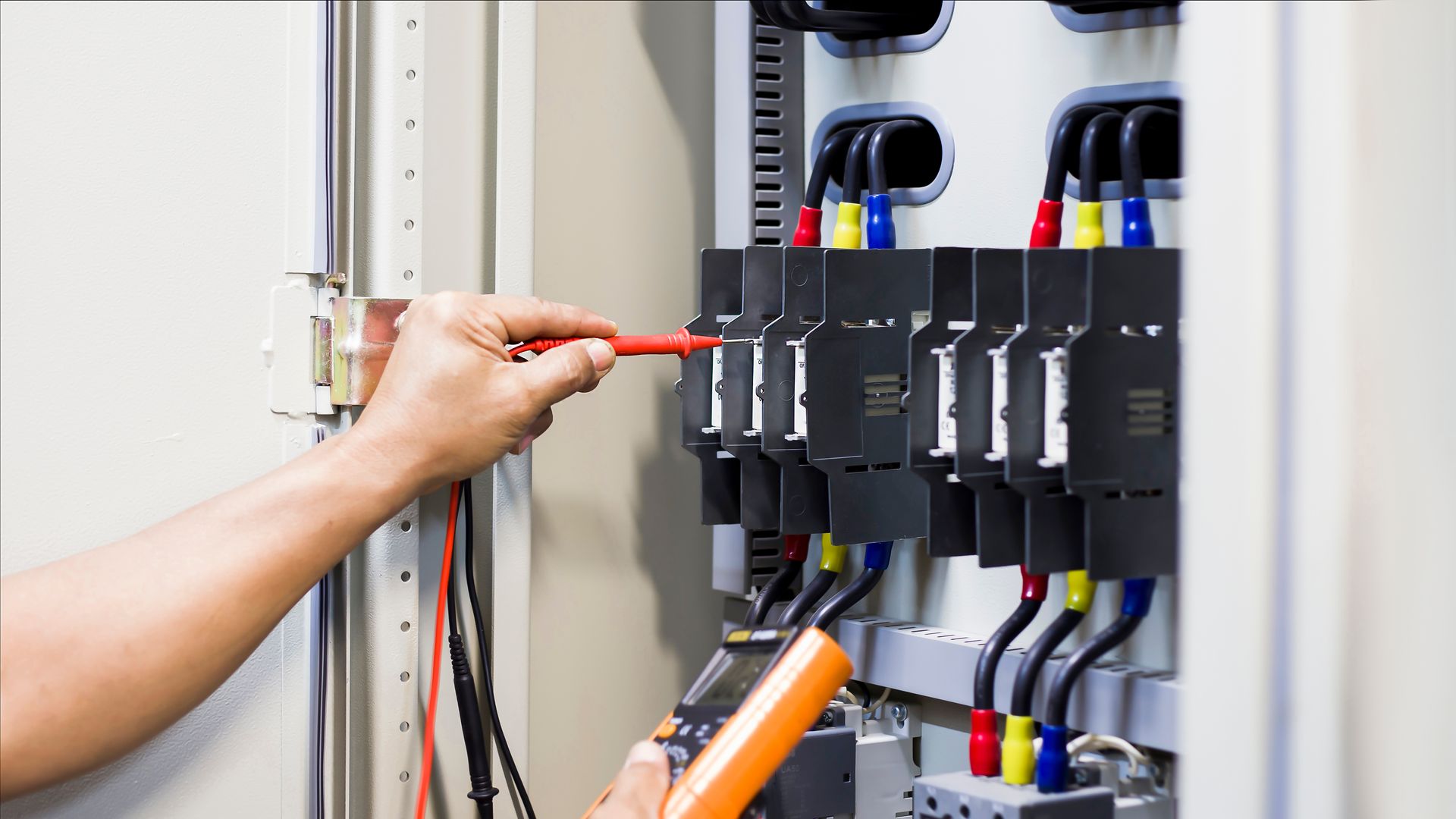

For over 70 years, Giering Metal Finishing has set a high standard for excellence in the metal finishing industry, combining cutting-edge technology with unparalleled craftsmanship and dedication. As a trusted family-owned business spanning three generations, we specialize in coatings that not only protect but elevate the performance and aesthetics of your products. Our commitment to precision ensures that every project meets the highest standards of quality and customer satisfaction. At Giering Metal Finishing, we don't just finish metal—we bring your vision to life.

OUR TRUSTED PARTNERS

Meet Our Leadership Team

Watch an interview with Giering Metal Finishing's President, George Giering.

With decades of expertise and commitment to excellence, we deliver solutions that set your products apart. Here's what makes us stand out:

Our Capabilities

At Giering Metal Finishing, our comprehensive range of capabilities is designed to meet the diverse needs of industries that demand excellence. Whatever your finishing challenge, we have the solutions to make your products excel.

INDUSTRIES served

From defense and aerospace to medical, our expertise supports some of the world's most critical industries. We deliver reliable finishes that ensure your products perform flawlessly in any environment.

WHY CHOOSE US

Choosing Giering Metal Finishing means partnering with a team committed to precision, quality, and reliability. With decades of expertise, cutting-edge technology, and trusted relationships with fellow finishers, we deliver tailored solutions and reliable recommendations beyond our specialty.

70 Years of Experience

Decades of proven expertise in solving complex challenges.

Customized Solutions

Every project is tailored to meet specific industry and requirements.

Comprehensive Capabilities

We offer a full range of finishing services under one roof.

Exceptional Support

Our team works closely with you, providing transparency.

Proudly Celebrating

70 year history

With over 70

years of experience, Giering Metal Finishing

has built a legacy of excellence in the metal finishing industry. As a third-generation, family-owned business, we combine time-tested expertise with continuous innovation to deliver unmatched quality and reliability.