ElectroCoating (ECOATing)

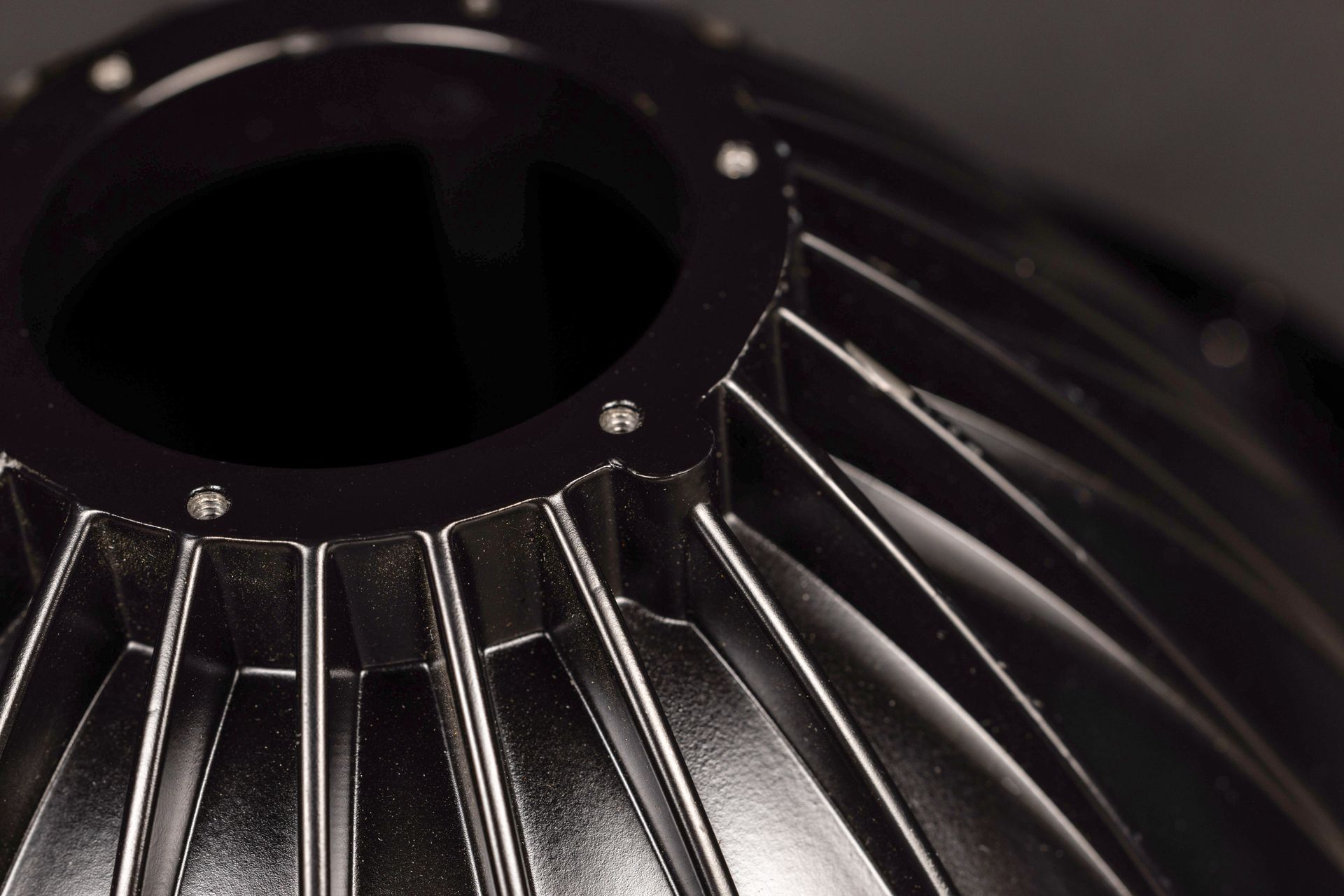

Electrocoating (Ecoat) delivers durable, uniform, and corrosion-resistant finishes for high-performance parts in industries like automotive, aerospace, and defense.

Electrocoating (Ecoat) Services in North America

CT's Metal Finishing Specialists

At Giering Metal Finishing, our electrocoating (ecoat) services provide a durable, high-performance solution for protecting and enhancing the appearance of your metal parts. With over 70 years of experience, we specialize in cathodic epoxy electrocoating using cutting-edge PPG Powercron 6000CX series systems to meet the highest industry standards.

What Is Electrocoating?

Electrocoating, or e-coat, is an immersion painting process that uses an electrical charge to apply an even, organic finish to electrically conductive parts. This advanced method combines precision with efficiency, coating every surface—including edges, corners, and recesses—with a low-profile film.

How It Works

This process provides excellent corrosion resistance, making it ideal for demanding applications in automotive, military, aerospace, and other industries.

Anodic Ecoating

In anodic ecoating, the part is the anode with a positive electrical charge. It attracts the negatively charged paint particles in the paint bath. Small amounts of metal ions migrate into the paint film, limiting the performance properties of these systems. Their primary use is for products for interior or moderate exterior environments.

Cathodic Ecoating

In cathodic systems, like those at Giering Metal Finishing, the product is negatively charged, which attracts the positively charged paint particles. This reversed polarity greatly reduces the amount of iron entering the cured paint film, enhancing the properties of the cathodic ecoated products. Cathodic coatings are high performance, thermoset coatings with excellent corrosion resistance (ie. epoxy) and can be formulated for exterior durability (ie. acrylic).

Eco-Friendly and Cost-Effective Coating Solutions

Ecoating is an environmentally friendly process that minimizes waste and emissions. It produces little to no hazardous air pollutants (HAPs) and ultra-low volatile organic compounds (VOCs), meeting RoHS, OSHA, and EPA standards. The system recycles unused paint and safely disposes of minimal waste, making it both eco-conscious and efficient. With automated application and precise control, e-coating reduces overspray and ensures durability, extending product life in harsh outdoor and indoor environments.

Ready to Protect and Enhance Your Parts?

At Giering Metal Finishing, our state-of-the-art ecoating services provide unmatched durability, precision, and environmental compliance. Whether you need corrosion resistance for high-performance parts or a reliable primer for additional coatings, we deliver consistent, high-quality results tailored to your specifications.

Let’s get started—call us at (203) 248-5583 or contact us today.

RELATED SERVICES

Quality & CONSISTENCY

Unmatched Quality, Proven Standards

At Giering Metal Finishing, quality is the cornerstone of everything we do. Utilizing advanced tools and rigorous quality control processes, we ensure each finish meets the highest standards for durability, consistency, and performance. From precise film thickness measurements to meticulous inspections, our team works diligently to adhere to your exact specifications.

Whether it's achieving flawless finishes, color matching, or delivering unmatched corrosion protection, our commitment to excellence ensures consistent results across every batch.

Our electrocoating processes

meet the following military

specifications:

industries

Common Uses for Ecoatings

Ecoating is used on a wide range of products, from automotive components to industrial equipment. Nearly all modern vehicles use e-coat as a primer, providing corrosion resistance that ensures extended warranties and superior performance. The environmentally friendly process and precise application make it a preferred choice for manufacturers worldwide.

Frequently asked questions

How does ecoating compare to other coating methods?

Ecoating offers more precise and uniform coverage than spray or powder coatings, especially on complex shapes and recessed areas. It also produces less waste and is more environmentally friendly.

Is ecoating environmentally safe?

Yes, ecoating is eco-friendly, producing ultra-low VOCs (volatile organic compounds) and little to no hazardous air pollutants (HAPs). It’s RoHS, OSHA, and EPA compliant, with minimal waste thanks to its recycling system.

What types of parts can be ecoated?

Ecoating is ideal for a wide range of electrically conductive parts, from small components to large assemblies, and can handle both simple and complex shapes. At Giering, we can process orders from single parts to millions.

WHY CHOOSE US

Choosing Giering Metal Finishing means partnering with a team committed to precision, quality, and reliability. With decades of expertise, cutting-edge technology, and trusted relationships with fellow finishers, we deliver tailored solutions and reliable recommendations beyond our specialty.

70 Years of Experience

Decades of proven expertise in solving complex challenges.

Comprehensive Capabilities

We offer a full range of finishing services under one roof.

Customized Solutions

Every project is tailored to meet specific industry and requirements.

Exceptional Support

Our team works closely with you, providing transparency.

Need it fast?

Expedited Services Tailored to Your Deadlines

At Giering Metal Finishing, we understand that sometimes strict deadlines call for urgent solutions. Our expedited services ensure your order is prioritized and completed faster than standard lead times, helping you stay on track without compromising quality.